Table of Contents

Choosing the Right Oil for Your Sewing Machine

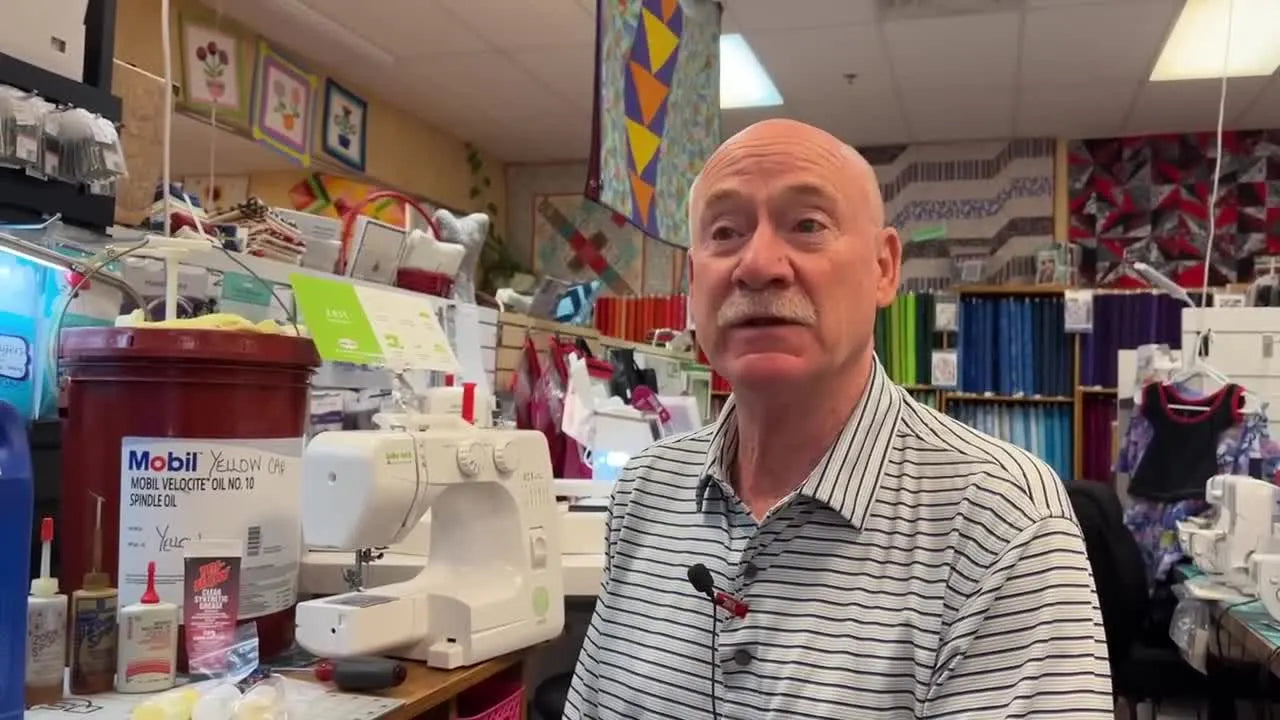

Jeff immediately establishes that choosing the right lubricant is non-negotiable for machine health.

Bernina’s Official Recommendations: Mobil Velocite Oil No. 10 and No. 6 are the stars of the session. The No. 10, housed in a yellow-capped dispenser, is Jeff’s go-to for general moving parts of all household machines.

He emphasizes Mobil’s corrosion protection and high oxidative stability. The lighter No. 6 (red-cap) variant is ideal for Bernina’s 9-hook systems used in the 7, new 5, and 4 series—critical areas that must be oiled daily.

Even if you own a different brand—Brother, Janome, or Juki—the takeaway is the same: pick oils formulated for fine machinery, never improvised substitutes. Many embroidery owners using magnetic embroidery hoops for bernina machines appreciate how consistent lubrication complements hoop stability.

Impact of Climate on Sewing Machine Oiling

A major variable Jeff highlights is humidity. Western Colorado’s 10–20 percent humidity evaporates oil faster than seaside test conditions.

If you sew in dry air, oil more often—simple as that. Machines stored in damp areas, conversely, may hold oil longer but risk corrosion. Climate awareness ensures smoother stitches whether you’re quilting in a mountain cabin or near the coast. And yes, even high-speed embroidery units fitted with magnetic embroidery hoops can lose lubrication faster when humidity drops.

Lubricants to Absolutely Avoid on Your Sewing Machine

Household shortcuts can be machine-killers. Jeff displays a row of “do not use” culprits, starting with 3-in-One oil. It’s perfect for squeaky doors, not delicate bearings.

He continues with Liquid Wrench, Vaseline, and heavy white grease—all prone to leaving residue or hardening.

The rule of thumb: if the label doesn’t say “sewing machine,” skip it.

When to Use Specialized Greases (and When Not To): Some operations do need grease. Tri-Flow Clear Synthetic Grease, for metal rubbing plastic (eccentrics and gears), is Jeff’s approved choice.

From the comments: Viewers echoed his caution, with one hobbyist noting Tri-Flow’s alcohol content makes it a short-term fix for vintage restorations only. Another restorer confirmed Jeff’s view—switch to pure sewing-machine oil once parts move freely.

Evaluating Other Popular Sewing Machine Oils

Singer’s branded oil remains a safe standby, though Jeff notes Mobil’s versions outperform it in protection.

Zoom Spout oilers are praised for reach but can leak if tipped. Always ensure yours says “sewing machine oiler,” not the general-purpose variant.

Commenters also debated mineral-oil alternatives like baby oil and food-grade mineral oil. Jeff clarified that genuine sewing-machine formulations, such as Zoom Spout or Velocite, are engineered for minimal residue.

If you’re maintaining an embroidery setup—say a multi-needle Brother unit using brother embroidery machine attachments—these same clear, light oils remain appropriate, just applied more frequently due to speed.

Understanding Tri-Flow and Spray Lubricants: Tri-Flow Superior Lubricant and LB5 spray each have niche uses. The sprays reach hidden squeaks without full disassembly but require care around electronics. Users of magnetic embroidery hoops for brother machines, where high stitch counts mean friction spikes, might use these for quick interim relief, followed by standard oiling.

Safe and Effective Cleaning with Canned Air

Jeff spends a full segment showing the right and wrong ways to use canned air. Dismantle your machine—nose cover first, then needle plate and bobbin case—before spraying.

Hold the can upright; never tilt or invert. The propellant becomes liquid moisture if upside down, a true hazard for metal parts. Blow from the back outward, not inward.

Small bursts only—think perfume spritz, not hairspray blast.

Excessive force drives lint deep instead of clearing it.

Comment Corner: Many viewers agreed this was the clearest explanation online; one added that in regions with chronic static, a quick handheld vacuum can pair well with canned air to trap loose lint safely.

Embroidery users cleaning around hoop master stations can apply the same logic: disassemble gently, clean outward, then re-oil moving rails.

General Maintenance Tips for Longevity

Jeff likens routine lubrication to regular doctor visits for your equipment. He advises oiling three or four times a year—or more if your climate is arid—and scheduling professional servicing every 18 months to two years.

Assessing the Quality of Older Oils: Bottles that tan over time are still viable if bubbles rise quickly when inverted. Darker oil isn’t ruined—it’s just tanned.

Thicker, sluggish fluid, however, belongs on door hinges, not your bobbin hook.

Store all oils away from sunlight. A cool cabinet ensures a decade of shelf stability.

From the comments, owners reaffirmed that even decades-old metal oilers from the 1950s work perfectly when filled with fresh, clear lubricant. Vintage machine fans using bernina magnetic hoops often keep both red-cap and yellow-cap bottles close by.

Quick Recap:

- Mobil Velocite No. 10 (yellow cap): general purpose

- Mobil Velocite No. 6 (red cap): Bernina 9-hook systems

- Tri-Flow grease: metal-to-plastic only

- Spray lubricants: for temporary spots only

- Canned air: use upright in bursts

Final thought—maintenance is universal. Whether your studio is equipped for quilting, tailoring, or running multi-needle embroidery with mighty hoops for brother, precision lubrication remains the simplest insurance for smooth stitching.